符合EFSA标准的工艺!从PET回收料中生产出食品安全级片材

发布时间:

2022-04-21

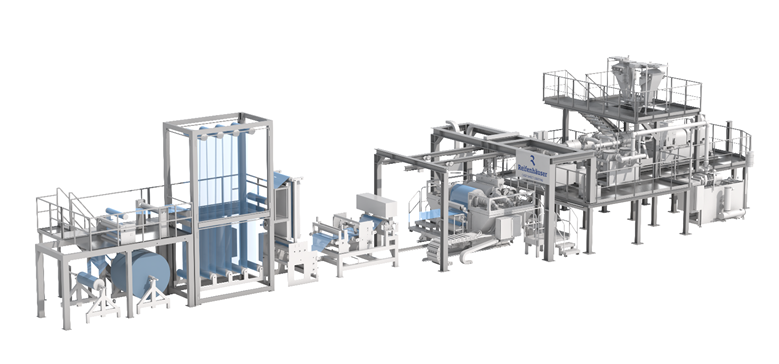

Reifenhäuser流延片材涂布--Reifenhäuser集团专门从事流延膜、片材和挤出涂布生产线的业务部门--已经开发出一种特别高效的生产工艺,可以将PET回收料直接加工成食品安全片材,而无需上游的干燥过程。

Reifenhäuser Cast Sheet Coating - the Reifenhäuser Group's business unit specializing in cast film, sheet extrusion, and extrusion coating lines - has developed a particularly efficient production process that allows PET recyclate to be processed directly into food-safe sheet without an upstream drying process.

如果回收材料与食品直接接触,则需要欧洲食品和安全局(EFSA)的特别认证。到目前为止,这种类型的食品包装用片材的生产一直非常费力和复杂。Reifenhäuser MIREX PET生产线现在简化了加工者的工作。通过使用同向旋转的双螺杆挤出机和专门开发的高性能真空系统,经认证的工艺可以直接加工PET回收材料,而不需要进行预处理和预干燥--这通常是一个需要的过程。这样,加工者就节省了对额外生产线组件的投资,避免了额外的能源和维护成本。它还可以快速更换材料和产品,例如从消费后PET瓶片(PCR)到工业后PET生产废料(PIR)或到原生PET。最终产品,如肉类包装吸塑盘,符合极高的卫生标准,并符合EFSA的要求,可直接与食品接触。

If recycled material comes into direct contact with food, it requires special certification from the European Food and Safety Authority (EFSA). Up to now, the production of sheet for food packaging of this type has been very laborious and complicated. Reifenhäuser MIREX PET lines now simplify the task for processors. By using a co-rotating twin-screw extruder and a specially developed high-performance vacuum system, the certified process allows PET recycling material to be processed directly without pretreatment and predrying - a process that is usually required. Processors then save their investment in an extra line component and avoid additional energy and maintenance costs. It also allows for quick material and product changes, for example from post-consumer PET bottle flake (PCR) to post-industrial PET production waste (PIR) or to virgin PET. The end product, such as a meat tray, then meets extremely high hygiene standards and is EFSA-compliant for use in direct contact with food.

Reifenhäuser流延片材涂布在主管部门的认证过程中为客户提供支持。这包括片状材料的清洁过程,进料的质量监测,以及按照EFSA规定的标准进行生产。

Reifenhäuser Cast Sheet Coating supports customers during the certification process with the competent authorities. This includes the cleaning process of the flake material, quality monitoring of the feed material, and production under the criteria defined by EFSA.

Reifenhäuser MIREX PET片材生产线从高达100%的PET瓶片中生产可持续的PET薄膜,用于直接接触食品(符合EFSA)。

另一个特点是自动记录相关的生产数据。EFSA的审计要求将认证过程中的配方和产品相关数据存储数年。ExtrusionOS生产合规性软件包是专门开发的,用于监测和安全地记录生产过程以及在实时数据库中遵守EFSA相关的安全标准。实时仪表板提供了当前生产参数和安全标准的透明显示,允许对异常情况作出快速反应。ExtrusionOS生产合规性是基于Reifenhäuser的连接解决方案ExtrusionOS核心和c.Hub中间件。它也可以加装到现有生产线上。

Another feature is the automatic documentation of relevant production data. EFSA audits require recipe- and product-related data from the certified process to be stored for several years. The ExtrusionOS Production Compliance software bundle was specially developed to monitor and securely document production processes and compliance with EFSA-related thresholds in a real-time database. A live dashboard provides a transparent display of ongoing production and thresholds, permitting rapid response to anomalies. ExtrusionOS Production Compliance is based on Reifenhäuser's connectivity solution ExtrusionOS Core & c.Hub Middleware. It can also be retrofitted to existing lines.

通过ExtrusionOS,生产数据也可以被转移到数字产品护照上--例如,通过开放的R-Cycle标准。数字产品护照是与初步产品和最终产品明确相连的数据记录,其中包含关于产品的材料、成分和利用的具体数据。特定的标记允许它们用于基于数据的、因而更精确的废物分类和回收过程,以及其他事项。

Via ExtrusionOS production data can also be transferred to a digital product passport - for example, via the open R-Cycle standard. Digital product passports are data records clearly linked to preliminary and end products that contain specific data on the materials, ingredients, and utilization of the product. Specific markings allow their use for data-based and therefore more precise waste sorting and recycling processes, among other things.

资料来源:https://mp.weixin.qq.com/s/bGeLHxhexskU6FhOMQvx_A

最新新闻